This comprehensive guide delves into the intricacies of NEC 250.122, a critical section of the National Electrical Code (NEC) that governs the sizing of equipment grounding conductors (EGCs). Understanding and applying these guidelines is paramount for ensuring the safety and reliability of electrical systems.

Why EGC Sizing Matters

EGCs, often referred to as ground wires, act as a safety net, providing a low-impedance path for fault currents to return to the source. This rapid diversion minimizes the risk of electrical shock and protects equipment from damage. NEC 250.122 ensures these “safety nets” are robust enough to handle potential surges of electricity, preventing hazards like fires and equipment failure.

Decoding NEC Table 250.122

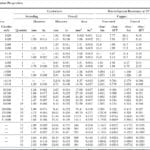

The heart of NEC 250.122 lies in Table 250.122, which directly correlates the rating of the overcurrent protective device (OCPD)—your circuit breaker or fuse—to the minimum required EGC size. This table simplifies the process, allowing electricians to quickly determine the appropriate EGC size for a given circuit. For example, a 15-amp breaker likely suggests a #14 AWG copper wire for the ground. Remember to consult the latest edition of the NEC Table 310.16 for the most accurate information on conductor ampacity and allowable overcurrent protection.

Navigating Special Cases

While Table 250.122 provides a baseline, certain situations warrant special consideration:

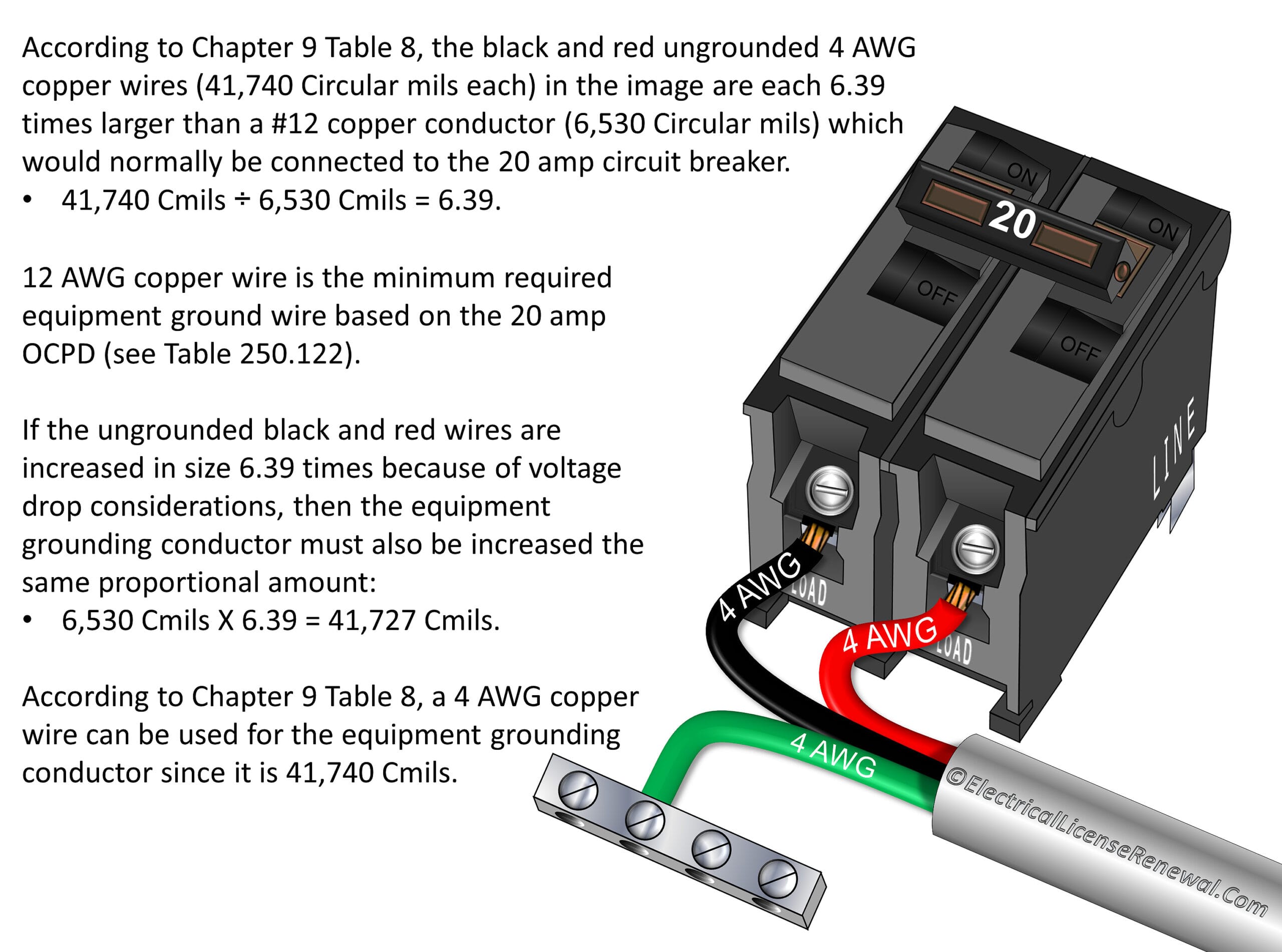

- Increased Conductor Size (250.122(B)): If power wires are upsized due to voltage drop—electricity losing power over long distances—the EGC may need a proportional increase. This ensures its effectiveness over the extended run. However, if the increase is only for voltage drop and not for a higher amperage load, the EGC size from Table 250.122 is likely sufficient.

- Multiconductor Cables (250.122(F)): For cables containing multiple conductors, the EGC size is determined by the OCPD protecting the entire cable, not individual wires within. This ensures the EGC can handle the total potential fault current of the circuit.

The Role of the Qualified Person (2020 NEC)

The 2020 NEC introduced a key change, empowering a “qualified person” to adjust EGC sizing based on specific factors beyond those listed in the table. This allows for a more nuanced approach in complex situations. However, the definition of a “qualified person” is left to the Authority Having Jurisdiction (AHJ), typically your local electrical inspector.

Key Considerations for EGC Sizing

- Wire Material: The type of wire—copper or aluminum—impacts the required EGC size. Copper’s higher conductivity often allows for a smaller gauge compared to aluminum.

- Oversizing: While exceeding the minimum EGC size from the table is permissible and may offer additional safety margin, excessively large EGCs add unnecessary cost and complexity to installations.

- Code Compliance: Always consult the latest NEC edition and local codes for the most up-to-date requirements. Regulations can change, and staying informed ensures compliance and optimal safety.

What is Section 250 of the NEC?

Section 250 of the NEC is the bedrock of electrical system safety, encompassing grounding and bonding practices. It establishes a framework for directing electrical currents safely and preventing hazards. This section is crucial for protecting both individuals and equipment from potentially dangerous electrical events.

Grounding vs. Bonding

Understanding the distinction between grounding and bonding is essential:

- Grounding: Creates a low-resistance path for fault currents to flow back to the earth, minimizing shock risks to people. Think of it as providing an escape route for stray electricity.

- Bonding: Connects metallic parts of the electrical system, eliminating voltage differences between them. This protects equipment and helps prevent fires by reducing the chance of sparks.

The Importance of the EGC

The EGC is the safety lifeline within an electrical system. By providing a dedicated path for fault currents to flow back to the source, it prevents dangerous voltage buildup on equipment. This conductor, sized appropriately using Table 250.122, is paramount for ensuring both personnel and equipment safety. It plays a crucial role in coordinating with the overcurrent protective devices, allowing them to react quickly and efficiently to ground faults.

Further Considerations within Section 250

Section 250 covers a wide range of topics related to grounding and bonding. For instance, 250.30 specifies requirements for grounding electrode conductor connections depending on the type of system (grounded or ungrounded), while 250.64 addresses grounding electrode connections in structures with multiple disconnecting means. It’s essential to consult section 250 in its entirety for the most comprehensive understanding of the topic.

What Size Ground Wire Does the NEC Require?

While Table 250.122 provides the minimum required EGC size, other factors may influence the final decision. Voltage drop, particularly over longer distances, may necessitate increasing both the current-carrying conductors and the EGC. This ensures the EGC remains effective in carrying fault current even with the increased resistance of a longer wire run.

Specific Applications

NEC 250.122 and related sections address specific applications:

- Flexible Cords: Flexible cords, like those on appliances, have their own set of rules for EGC sizing based on conductor size (generally those with conductors larger than 10 AWG have their EGC sized per 250.122).

- Parallel Conductors: Circuits using parallel conductors, where multiple wires share the electrical load, also have specific EGC sizing requirements outlined in 250.122(F).

Putting It All Together

NEC 250.122 plays a vital role in electrical safety. By choosing the correct EGC size and considering factors like voltage drop and specific application requirements, electricians ensure a secure electrical environment. While current research suggests these guidelines offer adequate protection, ongoing advancements in electrical technology may lead to future revisions. Staying informed about updates and best practices is crucial. Remember, if uncertainties arise, consulting a qualified electrician is always the best course of action. They can provide expert guidance and ensure your electrical system meets all safety and compliance standards. Delving deeper into the fascinating realm of occular systems can further broaden your understanding of intricate networks.

| OCPD Rating (Amps) | Minimum Ground Wire Size (AWG Copper) |

|---|---|

| 15 | 14 |

| 20 | 12 |

| 30 | 10 |

| 40 | 10 |

| 60 | 10 |

| 100 | 8 |

| 200 | 6 |

| 300 | 4 |

| 400 | 3 |

| 500 | 2 |

| 600 | 1 |

Note: This table is a simplified example. Always refer to the latest edition of the NEC for the most accurate and up-to-date information. Also, remember that local codes may have additional requirements.

1 thought on “Understanding NEC 250.122: A Practical Guide to Equipment Grounding Conductor Sizing”

Comments are closed.