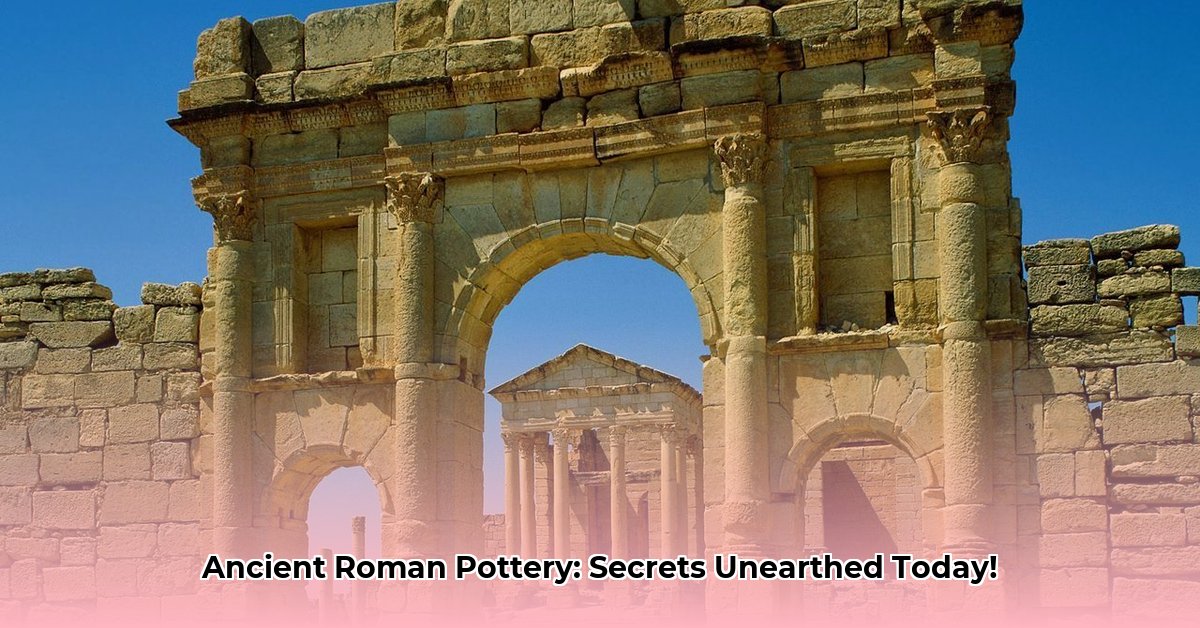

Have you ever wondered what ancient Romans ate from, stored their goods in, or how they conducted trade across their vast empire? A significant answer lies within something surprisingly simple yet profoundly complex: pottery. Roman pottery serves as more than just ancient dishes; it acts as a collection of time capsules, revealing profound insights into their daily lives, economic activities, and societal structures. This comprehensive study delves into these ubiquitous clay creations, from the refined tableware gracing Roman dinner parties to the robust containers crucial for transporting commodities like wine and olive oil.

Unlike the ancient Greeks, who frequently regarded pottery as a canvas for elaborate artistic expression through painting, the Romans primarily viewed it as a practical necessity, often crafted on a mass, industrial scale. This emphasis on utility and standardization, rather than painted decoration, is sometimes misinterpreted as a lack of artistry. However, Roman pottery showcases a different form of artistic and technical mastery, often mimicking the more prestigious forms and relief decoration of metalwork and glass, and reflecting a pragmatic genius for efficiency.

We will explore how these vessels were indispensable for commerce, uncover the evolution of pottery styles across different regions, and understand how archaeologists today utilize pottery fragments to pinpoint the precise location and era of past human settlements. So, whether you are a history enthusiast, a student, or simply curious about ancient Rome, join us as we unearth the secrets embedded in these everyday objects.

The Diverse World of Roman Ceramics: Form and Function

Roman pottery broadly falls into two principal categories: fine wares, intended primarily for dining and serving, and coarse wares, which served a range of utilitarian purposes from cooking to storage and transport. This division, however, sometimes blurred, especially with local provincial products that were often multi-purpose.

Fine Wares: Elegance at the Roman Table

Fine wares were crucial for formal dining, prized for their decorative and elegant appearance. Among the most distinguished examples was terra sigillata, a vibrant, glossy red-slipped ware. Initially produced in large-scale workshops in Arretium (modern Arezzo) in Tuscany from the 1st century BC to the early 1st century AD, this pre-eminent type of fine pottery was later succeeded by Samian ware, manufactured extensively in Gaul (modern France and Germany). These factories operated on industrial lines, producing highly standardized products.

The distinct reddish-orange to bright red surface and fine fabric of terra sigillata are due to a highly refined clay slip applied before firing. Decoration often featured intricate molded relief scenes—depicting pagan deities, mythological tales, genre scenes, flora, or fauna—rather than painting. The names of many potters and factory owners, such as Cnaius Ateius (a prominent producer whose stamps are found on wares produced in Pisa, Lyon, and La Graufesenque), are known from the potters’ marks frequently applied to fine wares. These marks provide invaluable information about production centers and distribution networks.

As the empire evolved, African Red Slip (ARS) ware emerged as the most widely distributed successor to the terra sigillata tradition, continuing in production much later, right through to the Islamic conquest. Manufactured primarily in Africa Proconsularis (modern Tunisia), ARS ware influenced other regional productions like Phocaean red slip. Unlike earlier terra sigillata, ARS ware often utilized separately made appliqué motifs and stamped decoration, with later examples frequently featuring Christian subjects and symbols.

Beyond these major red-gloss wares, other fine pottery types included delicate, thin-walled drinking vessels and pieces finished with vitreous lead glazes, which varied in color from amber to brown and various shades of green, typically used for small, decorative items. Egyptian faience, a non-clay ceramic, also continued to be produced, with some vessel shapes directly influenced by Arretine ware.

Coarse Wares: The Backbone of Daily Life

In contrast to fine wares, coarse wares were the everyday pottery jars, dishes, and bowls used for cooking, food preparation, and the storage and transport of goods. Often made and bought locally, these typically undecorated vessels were robust and functional, designed to withstand the rigors of daily use. From Britain to Egypt, local pre-Roman traditions in cooking wares often continued for centuries with minimal changes, reflecting the practical, regional nature of their production.

Notable examples include ollae (cooking pots for boiling and stewing) and mortaria. The mortarium was a robust, shallow bowl with a gritty internal surface, explicitly designed for grinding and pulverizing ingredients with a pestle. As the Roman equivalent of a food-processor, its widespread adoption across the empire, particularly in provinces like Britain, is a key indicator of “Romanization” and the spread of Roman culinary practices. Many mortaria also bore workshop or maker’s stamps, aiding archaeologists in understanding trade patterns and the Roman economy.

Crafting Clay: Production Techniques and Artisanry

The creation of ancient Roman pottery demanded specialized skills and sophisticated techniques, often passed down through successive generations. Roman potters were highly skilled artisans who possessed an intricate understanding of how to select and precisely blend various types of clay to achieve the desired consistency and workability for different vessel types. They frequently incorporated additives such as sand or crushed pottery fragments (known as grog or testacea) into the clay mixture, which improved its pliability, reduced excessive shrinkage during drying, and added strength. Quality control began at this initial stage, with craftsmen testing clay samples to ensure consistency and performance.

Forming Techniques and Standardization

Roman potters utilized a range of advanced forming techniques:

* Wheel-throwing: For symmetrical vessels such as plates, bowls, and cups, the pottery wheel was universally employed. Plain sigillata table vessels, for example, were made on the wheel using templates to create precise and standardized profiles, facilitating firing, storage, and transport of the immense quantities produced.

* Coil-building: For larger containers like dolia (large storage jars) or the bodies of amphorae, the methodical coil-building technique was used, where clay coils were stacked and smoothed.

* Molding: This technique was crucial for mass-produced items, particularly relief-decorated fine wares like terra sigillata and common oil lamps. For terra sigillata, a pottery bowl mould was decorated in intaglio using individual stamps (poinçons) or small wheels (e.g., ovolo design); once fired, this mould was used to press new bowls. Closed forms like jugs were rarely molded in their entirety; instead, molded appliqué motifs (sprigs) and barbotine decoration (slip-trailing) were used to create raised designs.

Kiln Technology and Industrial Scale

Roman kilns were

- Conquer Your Exam: Ancient Greece Quiz Ace It Now! - August 13, 2025

- Unlock lost flavors: Ancient Roman recipes you can make now for a taste of history! - August 13, 2025

- Unlock Empire Secrets: Ancient Rome Map Labeled, Interactive Insight Awaits - August 13, 2025