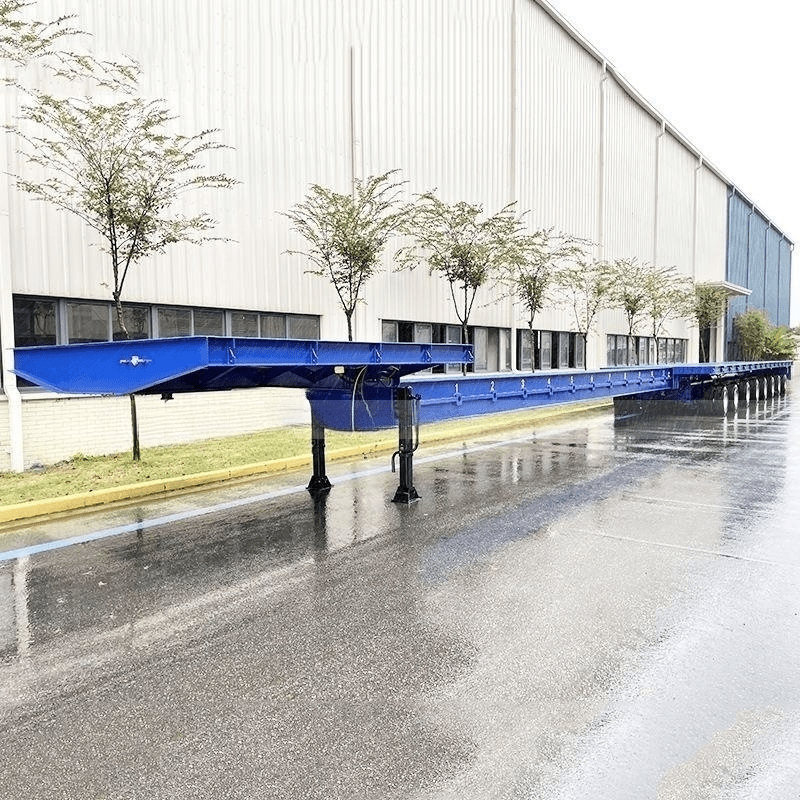

Choosing the right lowboy trailer is a major decision, especially when you’re hauling heavy equipment. It’s not just about the initial purchase; it’s about long-term efficiency and safety. This guide will help you navigate the process, explaining the different types, features, and considerations involved in finding and maintaining the best lowboy for your needs. Learn about lowboy trailer components and selection.

Understanding Lowboy Trailers: Types and Features

Lowboy trailers are designed for hauling oversized or heavy loads, but there’s more to them than meets the eye. Let’s break down the key variations to help you understand which type best suits your operation including lowboy trailer designs.

First, consider the gooseneck – the crucial connecting point between the towing vehicle and the trailer. Fixed goosenecks are a simpler, usually cheaper option, and offer the lightest weight, but they limit your flexibility. They also sacrifice the ability to detach and load over the front. If you frequently change cargo, a detachable hydraulic gooseneck might be a better investment – giving you the fastest and easiest way to detach, and the ability to easily detach the gooseneck for easier loading and unloading. Detachable mechanical goosenecks and folding options provide other unique advantages, depending on your specific needs. A mechanical folding gooseneck (MFGN) has a deck that folds down to ground level to provide a ramp for trailer loading. Think about how often you’ll be unloading and loading, and the sizes and types of equipment you’re transporting. What kinds of loads are you typically hauling? This will heavily influence your best choice.

Next, let’s talk about the suspension. A simple spring suspension is the lowest cost, however, it has a rougher ride and adds more stress to the trailer. Air and hydraulic suspension systems offer a significantly better ride, especially when traversing rough terrain. Air rides can also be adjusted for a higher or lower deck height. This is because they better distribute the weight of the load. Independent suspension systems – where each wheel has its own suspension – are the best for a smooth ride, particularly on uneven surfaces, offering more stability, greater steering angle and more travel. Your choice depends on your typical hauling routes and the sensitivity of your cargo to bumps and jolts. Consider the trade-offs between cost, maintenance, and ride quality when choosing a suspension. Understanding heavy haul trailer features can reduce downtime.

Finally, the trailer’s steel construction is key. Mill-rolled beams save money, although being around 4,000–6,000 lb (1,814–2,722 kg) heavier, they also reverse camber after a few years due to the much-lower strength of the main beams. However, high-strength T1/A514 beams save weight and allow more versatile engineering of the trailer; they are cut to the highest-strength shape possible and welded together, offering far greater durability and longevity, particularly crucial when hauling exceptionally heavy or oversized loads. While the initial cost might be higher, these stronger beams will likely result in lower long-term maintenance expenses and a longer lifespan for your trailer. Think about the total cost of ownership over time—which option provides the best return on your investment?

Optimizing Your Lowboy Trailer Operations

Owning a lowboy isn’t just about buying the right trailer. Efficient operation requires diligence and proper maintenance. Before each haul, perform a thorough inspection. This isn’t optional; it’s an essential safety measure. Check tire pressure (uneven pressure can lead to accidents!), brake function (critical for safe stopping), and lubricate all moving parts. Neglecting routine maintenance could lead to costly repairs or even dangerous breakdowns. Ensure efficient heavy equipment transport through proper maintenance.

Securing your cargo is paramount. Incorrect load securing is a major cause of accidents. Use appropriate chains, straps, and other restraints. Always follow all relevant regulations and best practices. These regulations – both local and federal – are complex and might differ by location, so always confirm the exact weight and dimension limits before you begin your haul. Never compromise on safety. Complying with oversized load regulations can save you money.

Lowboy Trailer Selection: Comparing Options

The table below helps you compare different lowboy trailer features. Remember, the “best” option depends entirely on your specific needs and priorities.

| Feature | Option 1: Basic | Option 2: Mid-Range | Option 3: Heavy-Duty | Key Considerations |

|---|---|---|---|---|

| Gooseneck Type | Fixed Gooseneck | Detachable Hydraulic Gooseneck | Detachable Hydraulic, Heavy-Duty | Frequency of load changes, type of cargo, ease of loading/unloading |

| Suspension System | Leaf Spring | Air Suspension | Air Suspension with Independent Axle | Terrain, load weight, ride quality, required comfort level, maintenance costs |

| Structural Steel | Mill-Rolled Steel | High-Strength Steel | High-Strength Steel, Reinforced Design | Load capacity, durability, longevity, initial investment vs. long-term costs |

Risk Mitigation Strategies: Preparing for the Unexpected

Even with the best equipment and planning, unforeseen issues can arise. Here’s a proactive approach to address potential problems:

- Hydraulic Gooseneck Failure: Regular maintenance is key. Consider redundant systems or emergency backups for added peace of mind.

- Trailer Structural Failure: Frequent inspections are non-negotiable. Replacing parts as needed extends the life and safety of the trailer.

- Air Suspension Leaks: Schedule regular leak checks; address any issues promptly.

- Improper Load Securing: Invest in thorough operator training and enforce strict safety protocols.

Long-Term Planning and Investing Wisely

Buying a lowboy trailer is a substantial investment. Don’t focus solely on the purchase price. Consider the overall cost of ownership. Factor in fuel costs, regular maintenance, potential repairs, insurance, and potential downtime. Think about your future needs: Will your business grow, requiring a larger or more specialized trailer in the future? A well-planned approach will minimize unexpected expenses and maximize your return on investment. Remember, proactive, routine maintenance isn’t just cost-effective; it’s essential for safety and preventing major issues down the road. Do you have a robust maintenance schedule already in place? Maximize heavy haul efficiency through long-term planning.

How to Calculate Total Cost of Ownership for Lowboy Trailers

Key Takeaways:

- The initial purchase price is just the tip of the iceberg when it comes to owning a lowboy trailer.

- Long-term expenses like maintenance, repairs, and downtime significantly impact your overall costs.

- Investing in high-quality components upfront can result in lower long-term expenses.

Lowboy trailers are workhorses of the heavy-haul industry. But simply buying one isn’t the end of the story. How to calculate total cost of ownership for lowboy trailers is a vital skill for any serious operator. Let’s break down the key elements. Learn about total cost of ownership and profitability.

Beyond the Sticker Price: Understanding Lowboy Trailer TCO

Think of it like this: buying a lowboy trailer is an investment, not just an expense. To truly understand its value, you need to look beyond the initial purchase price. Total Cost of Ownership (TCO) considers everything from initial costs to the trailer’s eventual resale—or scrap—value. This comprehensive view provides a clearer picture of your long-term investment. Effective lowboy trailer investment strategy is essential.

The Major Cost Components

Several key factors contribute to your lowboy’s TCO. These include:

- Purchase Price: The initial investment, this element is only the starting point.

- Maintenance and Repairs: Expect regular maintenance, preventative and reactive. Budget for both.

- Fuel Costs: Fuel efficiency varies with load, terrain and trailer design.

- Downtime: Factor in time lost due to repairs. Lost revenue is a significant expense.

- Insurance and Permits: These costs are often overlooked. Check your local regulations.

- Resale or Scrap Value: What will your trailer be worth when you’re done with it? Quality construction and conscientious maintenance improve resale rates.

Calculating Your Lowboy’s TCO: A Step-by-Step Guide

- Gather Data: This includes the initial purchase price, projected maintenance schedules and costs, fuel consumption estimations, insurance premiums, and permit fees.

- Estimate Annual Costs: For maintenance and repairs, use historical data or manufacturer estimates. Create a realistic annual budget for fuel.

- Project Lifespan: How many years do you plan to use this lowboy? This factor is critical for calculating depreciation.

- Depreciation Calculation: Estimate the trailer’s value at the end of its projected service life. The difference between the purchase price and the residual value represents depreciation. Allocate this cost across the trailer’s lifespan.

- Sum the Costs: Add up the initial purchase price, total maintenance/repair costs, fuel estimates, insurance, permits, and depreciation. The result represents your TCO.

Remember, accurate estimation is key. Accurate cost estimation requires careful data collection and realistic predictions of operational parameters.

Optimizing Your Lowboy TCO: Key Strategies

- Prioritize Quality: Investing in a well-built, durable trailer results in fewer repairs and increased longevity.

- Regular Preventative Maintenance: Catch minor issues early, saving you money on major repairs down the road.

- Smart Route Planning: Optimize routes to reduce mileage and fuel consumption.

- Proper

- Scipio Africanus: Hannibal’s Nemesis: Rise, Fall, and Legacy - August 2, 2025

- Unveiling Superorganisms: Are Ant Colonies One Mind? - August 2, 2025

- Unveiling The Northern Lights (Aurora Borealis): The Science Behind Nature’s Light Show: 2025 Guide - August 2, 2025