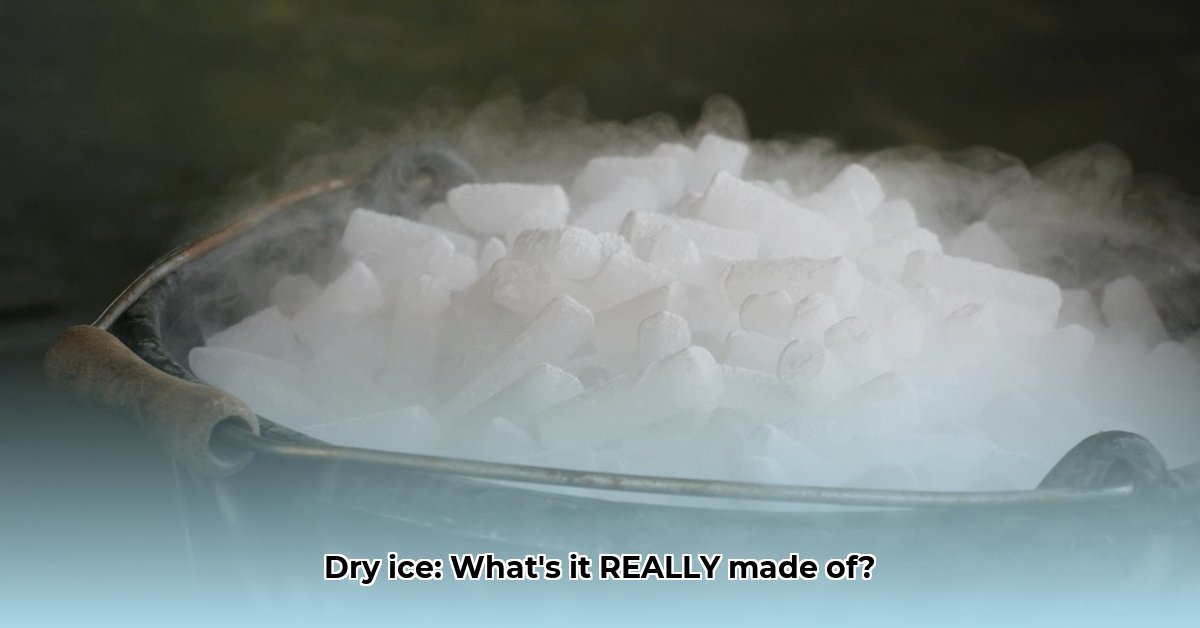

Ever seen that spooky fog rolling across a Halloween haunted house or maybe swirling from a scientist’s experiment? That’s dry ice! It’s super cool (literally!), but what exactly *is* it, and how do they make it? This article breaks down the process, from the initial ingredients to the final chilly product. We’ll cover how it’s made in different shapes and sizes, what you need to know to handle it safely (it’s colder than your freezer!), and even how dry ice is used in everything from keeping food fresh to making cool special effects. We’ll also look at how the process is changing to be more eco-friendly. Get ready to learn all about this amazing, and slightly mysterious, substance!

Unveiling the Composition of Dry Ice and Production Processes

Ever wondered about that amazing, spooky fog at a Halloween party or in a theatrical production? It’s dry ice! But what exactly is it? Simply put, dry ice, that chilly, white solid, is frozen carbon dioxide (CO2). However, the journey from invisible gas to that solid wonder is surprisingly interesting – and not as straightforward as you might think. This complete guide will walk you through the process and explain its properties, applications, associated safety measures, and environmental impact.

The Amazing Transformation: Understanding CO2 Phase Transitions

Dry ice isn’t something that’s mined from the earth; it’s manufactured. The whole process begins by capturing carbon dioxide gas. Where does this CO2 come from? Often, it’s a byproduct of various industrial processes – think power plants or factories that produce things like ammonia or ethanol. This captured gas isn’t pure enough for dry ice production, so it needs a bit of a cleanup.

Step 1: Purification – Getting Rid of the Impurities

Imagine refining crude oil into gasoline. You’ve got a complex mixture, but you need to isolate specific hydrocarbons. It’s similar with CO2 gas. The gas is purified, carefully removing any unwanted elements like water vapor, nitrogen, or other gases. Standard purification methods include absorption, adsorption, and cryogenic distillation. This ensures that the final product is pure and safe for its intended uses.

Step 2: Liquefaction – Turning Gas into Liquid

Next comes the transformation into a liquid. The purified CO2 gas is squeezed under high pressure (typically around 870 psi) and cooled down significantly to approximately -30°F (-34°C). At this temperature and pressure, CO2 transitions from a gaseous state to a liquid state. The liquefaction process usually involves refrigeration systems using refrigerants like ammonia or specialized hydrocarbons.

Step 3: Solidification – The Instant Freeze

Now for the exciting part! The liquid CO2 is then rapidly expanded into a low-pressure environment through a nozzle or valve. Because of the Joule-Thomson effect, rapid expansion causes a significant temperature drop. This rapid pressure drop causes the liquid to freeze instantly, resulting in the formation of dry ice “snow,” a fluffy, white solid.

Step 4: Compression and Formation

The dry ice snow is then collected and compressed using hydraulic presses. The compression process compacts the snow and molds it into various forms, such as slices, blocks, pellets, or nuggets. The type of mold used depends on the intended application of the dry ice. For example, small pellets are often used in food preservation and shipping, while larger blocks are used for cooling and industrial purposes.

Dry Ice’s Unique Properties and Widespread Applications

The most remarkable thing about dry ice is how it changes states: it undergoes a process called sublimation. This means it turns directly from a solid into a gas (carbon dioxide) without ever becoming a liquid. This is what creates that eerie fog you often see; when it turns into a gas, it creates a dense fog effect, perfect for spooky Halloween displays or theatrical performances. Combined with its extremely cold temperature (-78.5°C or -109.3°F), this makes it useful in many diverse applications.

Dry ice is used everywhere:

- Keeping Foods Fresh: Think of it as a super-powered ice pack for long-distance food transportation of items like ice cream, meat, and produce.

- Industrial Cleaning (Dry Ice Blasting): It’s used to blast away dirt and grime from machinery, molds, historical restoration projects, and even delicate surfaces.

- Medical and Scientific Applications: It’s used in labs to keep things super cold for preserving biological samples, transporting vaccines, and cryopreservation.

- Entertainment Industry: Dry ice creates special effects for concerts, theatrical performances, haunted houses, and film productions.

- Pest Control: It’s used for rodent and insect control by displacing oxygen in enclosed spaces.

- Wine Industry: Dry ice is used during wine fermentation to control temperature and prevent oxidation.

Safety First: Handling Dry Ice Responsibly

While fascinating and useful, dry ice isn’t something to handle carelessly. Its extremely low temperature can cause serious frostbite or cryogenic burns if you touch it directly.

Here are some essential safety precautions:

- Wear Protective Gear: Always wear proper insulated gloves (cryo gloves) and protective eyewear (safety glasses or goggles) when handling dry ice.

- Avoid Skin Contact: Never touch dry ice with bare skin. Use tongs, scoops, or insulated gloves to handle it.

- Ventilation is Key: Because sublimation releases carbon dioxide (CO2) gas, ensure sufficient ventilation to prevent asphyxiation, especially in enclosed areas.

- Proper Storage: Never, ever store dry ice in an airtight container, as the pressure build-up from the gas can cause a dangerous explosion. Use a well-ventilated cooler or insulated container.

- Transportation: When transporting dry ice in a vehicle, keep the windows slightly open to allow for ventilation.

- Disposal: Allow dry ice to sublimate in a well-ventilated area. Do not dispose of it in drains, sewers, or trash cans.

- Never Ingest: Under no circumstances should dry ice be ingested.

Environmental Impact: A Complex Carbon Footprint Analysis

A common question people ask is about its environmental impact. Well, it’s really complicated. While dry ice production uses CO2, its overall impact depends heavily on the CO2 source.

Here’s a breakdown of the key considerations:

Source of CO2: If the CO2 is captured from industrial processes that would otherwise release it into the atmosphere (e.g., ethanol plants, ammonia production, power plants with carbon capture technology), the environmental impact can be significantly reduced. In this case, it can be viewed as a form of carbon capture and utilization (CCU).

Fossil Fuel-Based CO2: If the CO2 is generated by burning fossil fuels specifically for dry ice production, the environmental impact is considerably higher. This contributes to greenhouse gas emissions.

Transportation: The transportation of CO2 and dry ice also contributes to emissions. Optimizing logistics and using fuel-efficient vehicles can help minimize this impact.

Energy Consumption: The energy required for CO2 capture, purification, liquefaction, and compression processes also plays a role. Improving energy efficiency and using renewable energy sources can reduce the carbon footprint.

Some experts believe that using industrial waste CO2 reduces the overall carbon footprint. However, the picture isn’t entirely clear. If the CO2 originates from the burning of fossil fuels (like coal or oil), then the process isn’t carbon neutral. A life cycle assessment is needed to account for all the emissions associated with the production, transportation, use, and disposal of dry ice. Ongoing studies are investigating the total effect of dry ice production on the environment.

The Future of Dry Ice Production: Sustainable Practices and Innovations

The future of dry ice likely involves making the process more efficient, sustainable, and environmentally friendly.

Here are some key trends and innovations:

- Carbon Capture and Utilization (CCU): Expanding the use of CCU technologies to capture CO2 from a wider range of industrial sources and use it for dry ice production.

- Renewable Energy: Powering dry ice production facilities with renewable energy sources like solar and wind power.

- Process Optimization: Improving the energy efficiency of CO2 capture, liquefaction, and compression processes.

- Alternative Refrigerants: Exploring alternative refrigerants with lower global warming potentials for use in the liquefaction process.

- Bio-Based CO2: Utilizing CO2 from bio-based sources, such as fermentation processes in biofuel production.

- Improved Insulation: Developing better insulation materials for dry ice containers to reduce sublimation rates and extend shelf life.

- Smart Monitoring: Implementing sensor technology to monitor CO2 levels and temperature during transportation and storage.

Finding ways to efficiently reuse and recycle other waste streams of carbon dioxide is also an important area of ongoing research.

Dry Ice Production: Weighing the Environmental Impact

| Pros | Cons |

|---|---|

| Excellent cooling and preservation | Presents safety risks (frostbite, asphyxiation) |

| Extremely versatile in various applications | Requires specialized handling and storage |

| Potentially environmentally friendly (if CO2 is responsibly sourced from industrial processes using carbon capture technologies) | Dry ice can be more expensive than some other refrigerants |

| Readily available in many regions | Potential for pressure buildup in sealed containers |